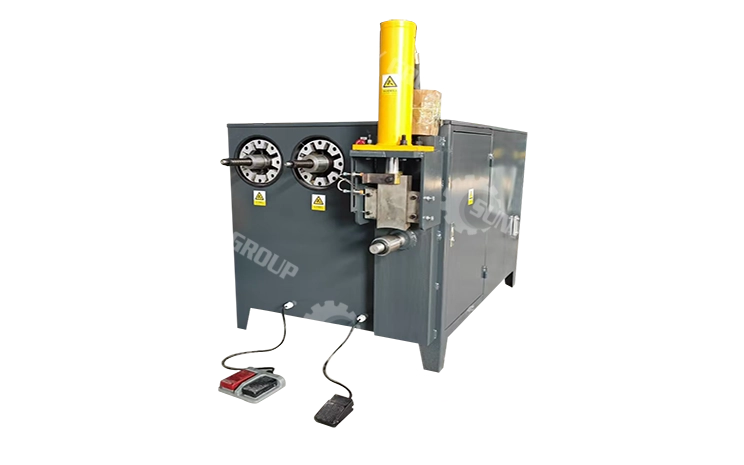

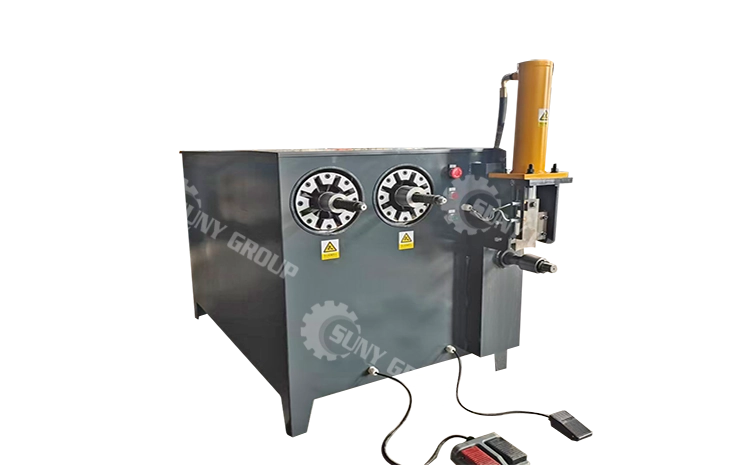

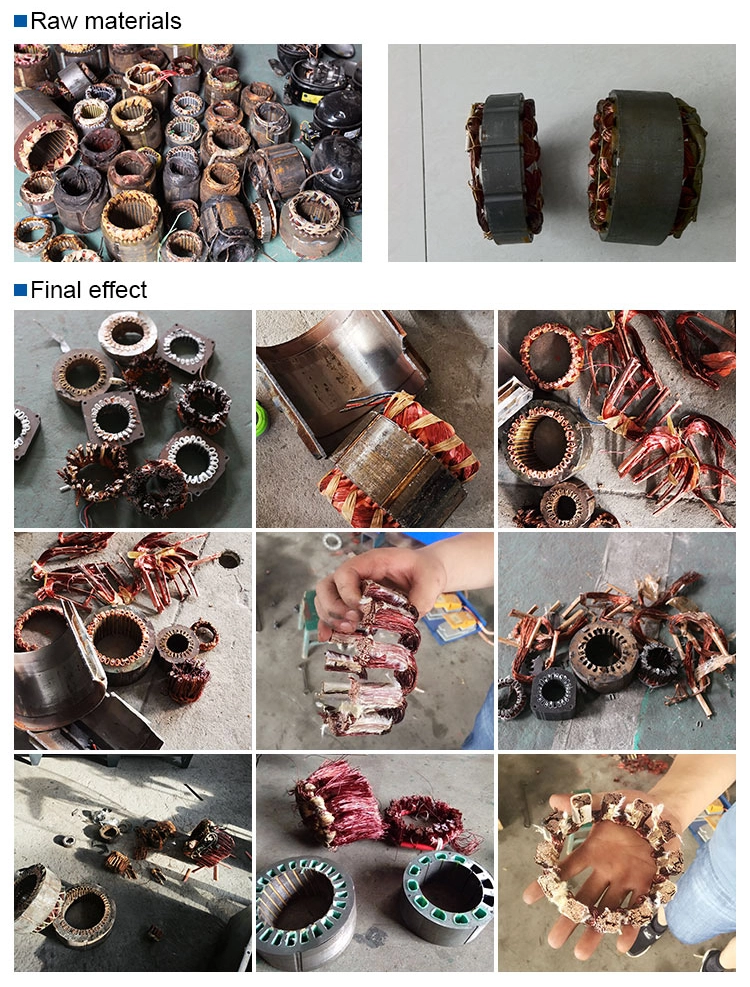

Core-Safe Motor Stator Dismantling Machine is designed for dismantling stators of small motors, including washing machine motors, industrial fan motors, and low-power motors. It features high cost-effectiveness and a com- pact footprint. The cutting tool removes copper windings from the stator end, while the hydraulic system quickly extracts the internal copper wires from the stator core.

The key feature of this equipment is its ability to preserve the stator core for reuse after dismantling, without damaging the stator core. This allows manufacturers to recycle stator cores, significantly reducing unnecessary waste.

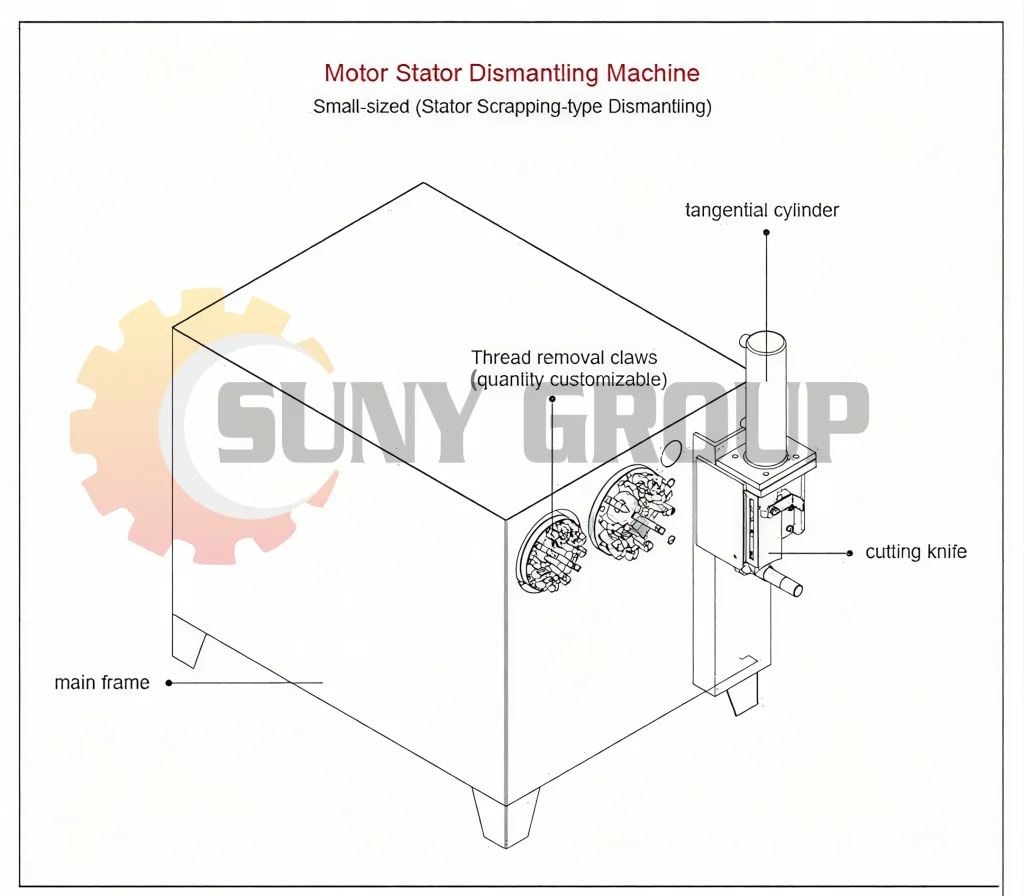

Main components of the equipment include: main frame, cutting mechanism, wire-gripping mecha- nism, electrical system, and hydraulic system.

The machine boasts a rational structure, simple operation, and safe, reliable performance. It can be equipped with various wire-dismantling molds, allowing users to select the appropriate mold based on stator size, effectively reducing labor intensity and improving production efficiency.

Operation process

A. Preparation

Fill the machine oil tank with #46 anti-wear hydraulic oil.

Connect power supply: 3-phase 380V 50Hz (4-wire system), urnless special voltage is required

Release the emergency stop button and press the green start tbutton to activate the motor.

B. Stator Cutting

Place the stator on the wire-cutting assembly.

Step on the cutting foot pedal to lower the blade and cut a section ofcopper windings

Rotate the stator and repeat the cutting process.

After a full rotation, one end of the stator windings will be completelysevered

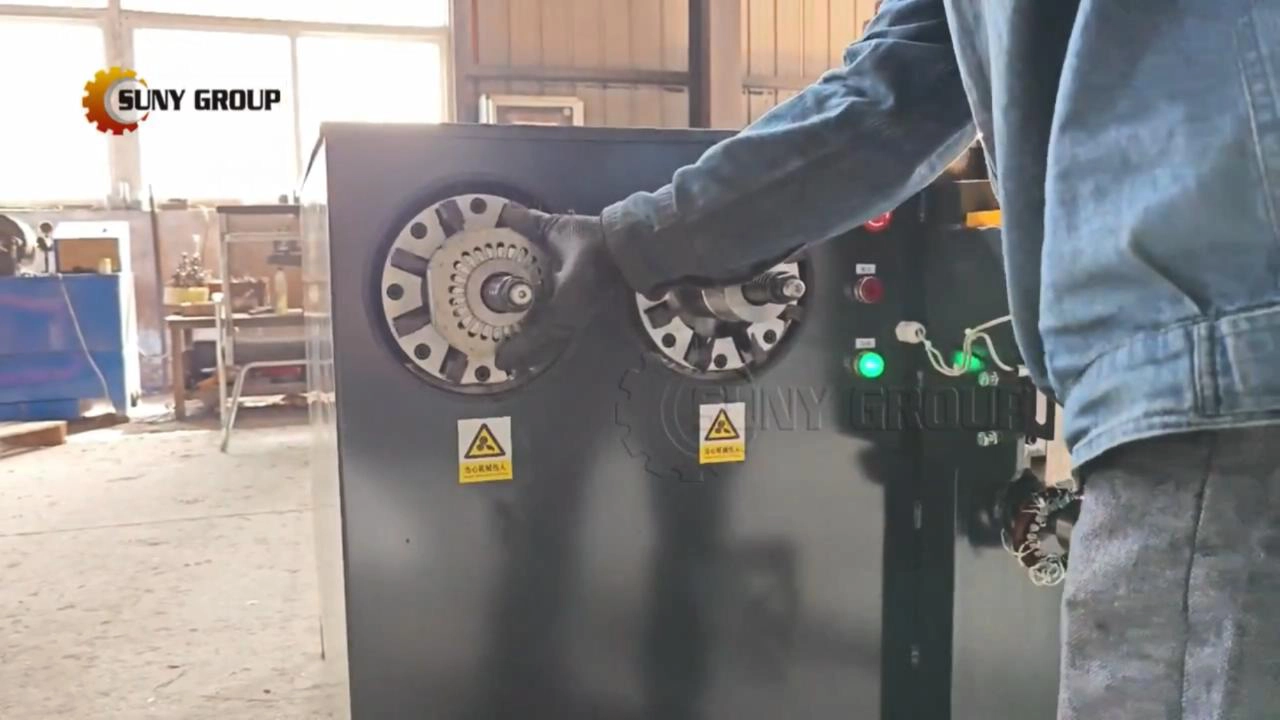

C. Coil Removal

Small Stator

Place the stator (cut end facing outward, uncut end inward) onthe wire-gripping mandrel.

Step on the coil removal foot pedal to extract the internal coppeer windings

Machine Structure