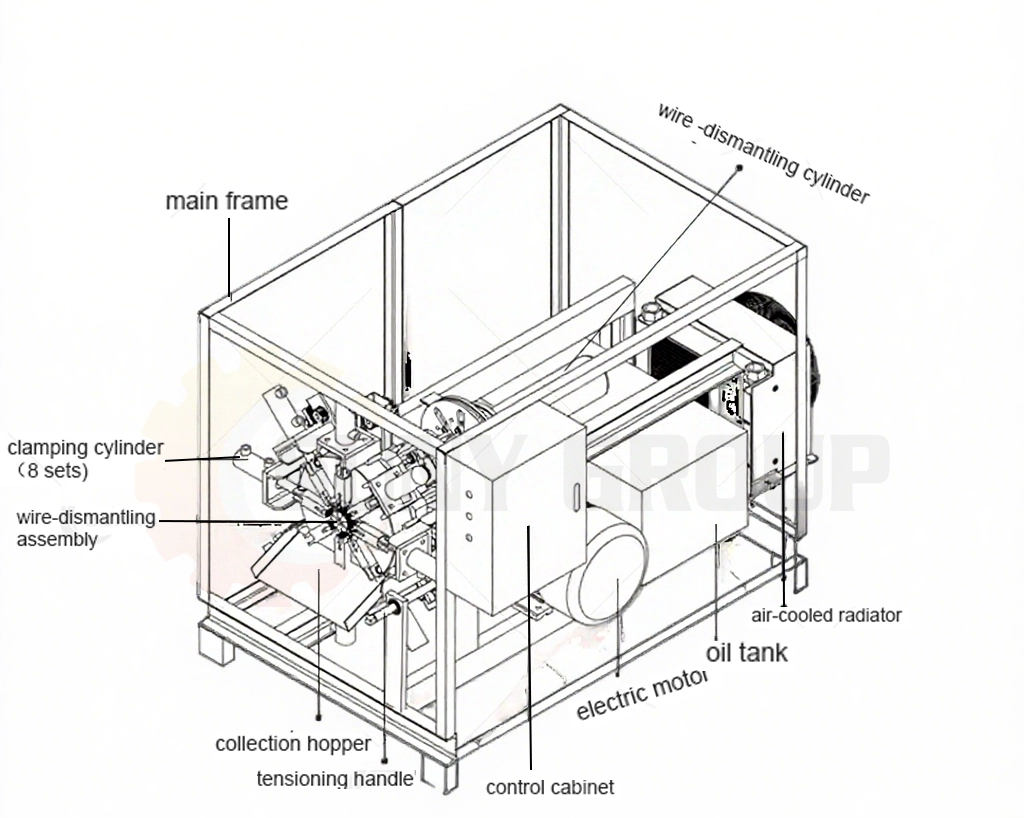

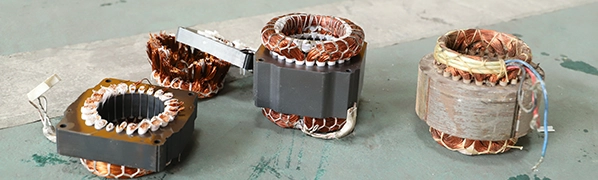

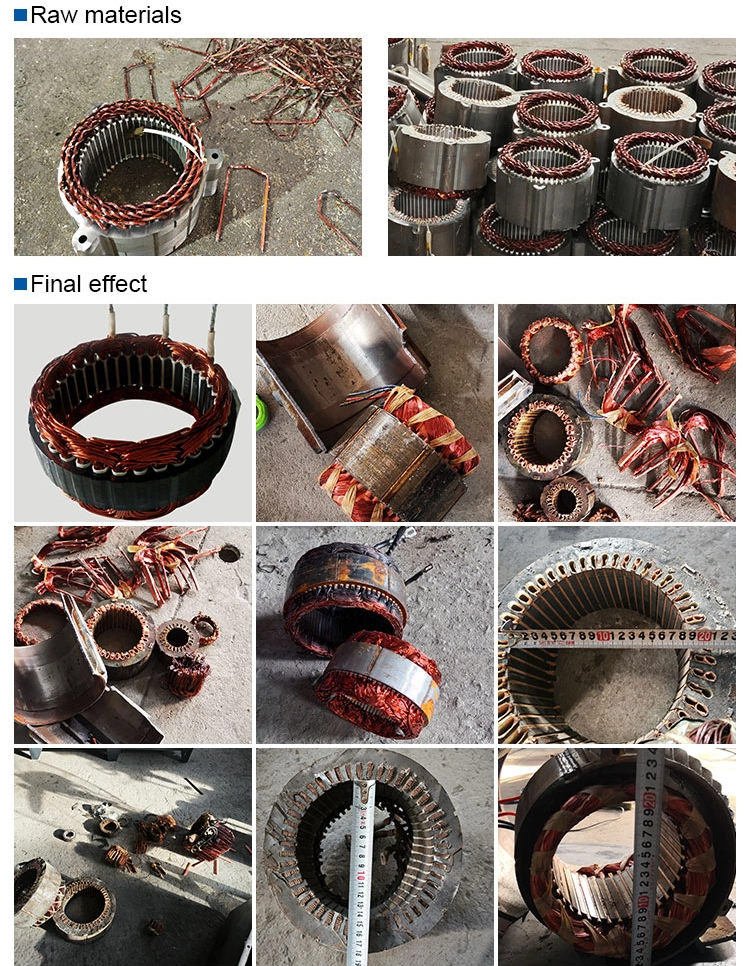

The Multi-purpose Motor Stator Dismantling Machine is specially designed for efficiently removing stator windings from new energy vehicle motors, automotive alternators, and conventional single-phase or three-phase motors. With its versatile, mold-free design, it adapts to different stator sizes without the need for replacement parts, offering superior compatibility compared to traditional copper extraction machines. Built with a robust main frame, self-adaptive clamping system, hydraulic cylinders, dismantling assembly, and integrated electrical and hydraulic systems, the machine combines safe and reliable performance with easy operation. It not only reduces labor intensity but also greatly enhances dismantling efficiency, making it an ideal solution for high-performance motor recycling and repair.

Operation process

A. Preparation

1.Fill the hydraulic oil tank with #46 anti-wear hydraulic oil.

2. Connect to a 3-phase 380V/50Hz power supply (except for specialvoltages)

3.Press the green start button to activate the motor.

B. Dismantling Procedure

1.Initial Cutting:

1.1 Cut off one end of the stator windings using a cutting tool,cor

1.2 Use our stator cutting machine to split the stator at the middlle.

2.Positioning:

2.1 Orient the stator with the cut end facing the machine.

2.2 Adjust the tensioning handle to match the core shaft size tothe stator’s inner diameter.

3.Dismantling:

3.1 Step on the foot pedal switch (momentary control)to initiateautomatic winding removal.

4.For Varnished/Compact Windings:

4.1Use our heating equipment for 5-10 seconds to soften the windings before dismantling.

Machine Structure