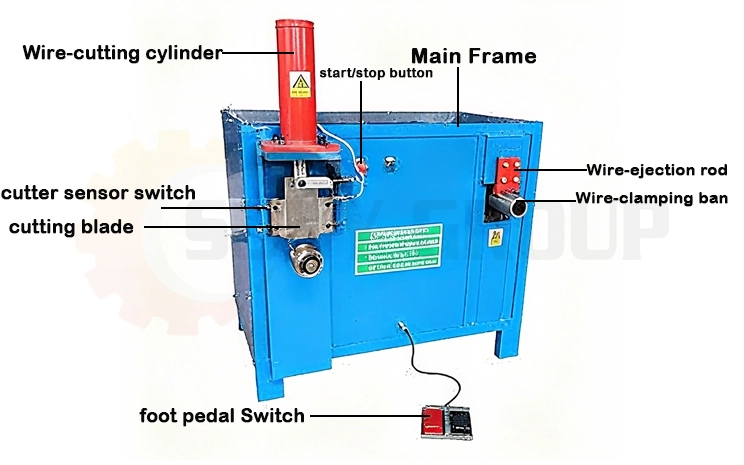

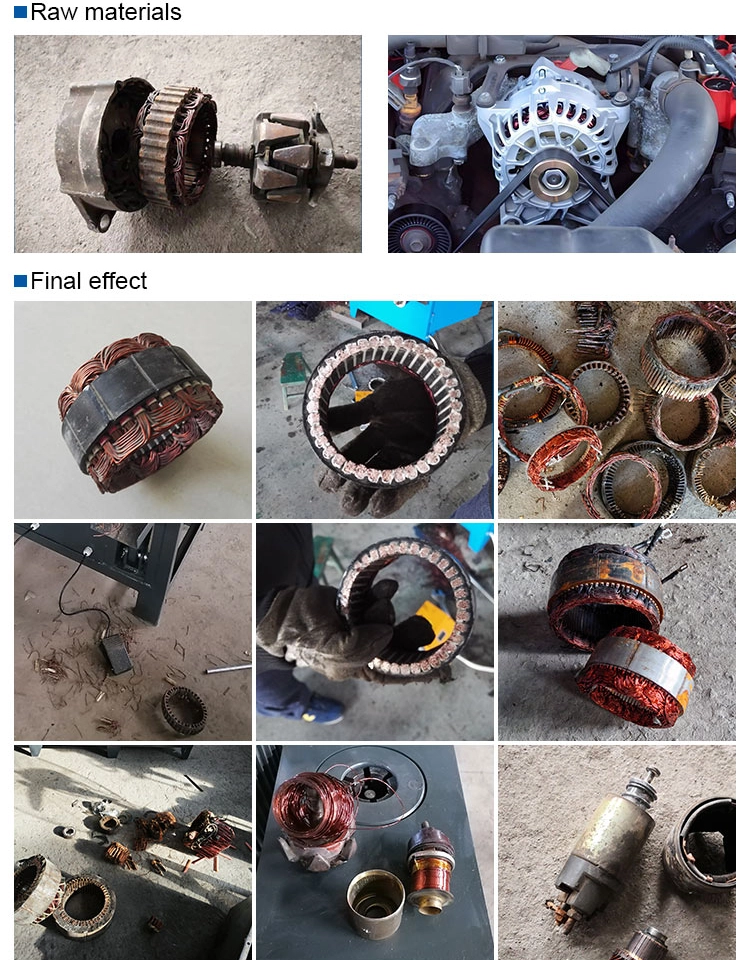

Automobile motor stator dismantling machine is mainly used for dismantling stator windings of automotive alternators. The cutting blade removes copper windings from one end of the alternator stator, followed by the wire-ejection rod sequentially extracting copper wires from the stator core. The machine can also integrate the function of dismantling starter solenoid coils, utilizing the existing hydraulic system to reduce procure- ment costs. The machine primarily consists of: main frame, cylinder assembly, wire-cutting assembly, wire-dis- mantling assembly, clamping assembly, electrical system, and hydraulic system. Featuring rational structure, simple operation, and safe/reliable performance, it effectively reduces labor intensity while improving production efficiency.

Operation process

A. Preparation

Fill the machine oil tank with #46 anti-wear hydraulic oil.

Connect power supply: 3-phase 380V 50Hz (4-wire system), unless special voltage is required.

Release the emergency stop button and press the green start button to activate the motor.

B. Stator Cutting

Place the stator on the wire-cutting assembly.

Step on the cutting foot pedal to lower the blade and cut a sectionof copper windings

Rotate the stator and repeat the cutting process.

After a full rotation, one end of the stator windings will be completely severed.

C. Coil Removal

Place the stator (cut end facing outward, uncut end inward)on the wire-gripping mandrel.

Step on the coil removal foot pedal to extract the internal copper windings

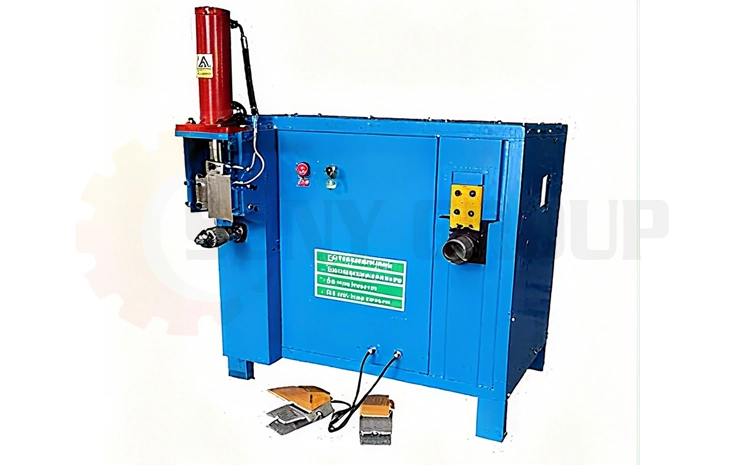

Machinery structure