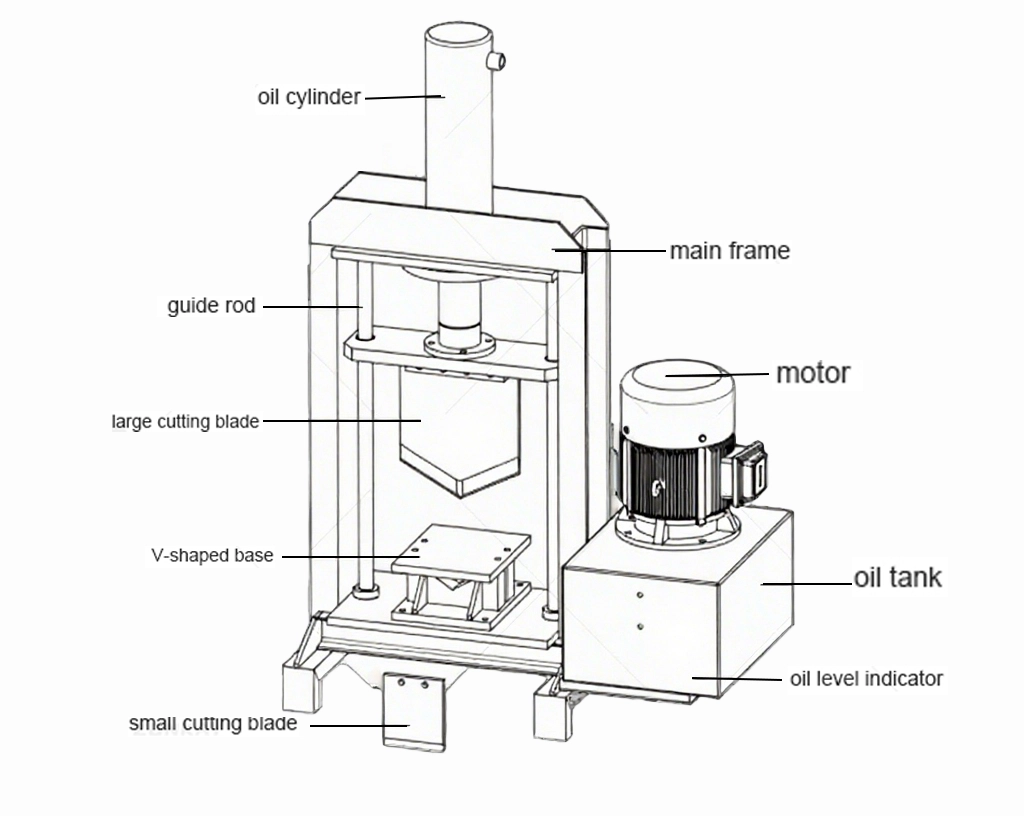

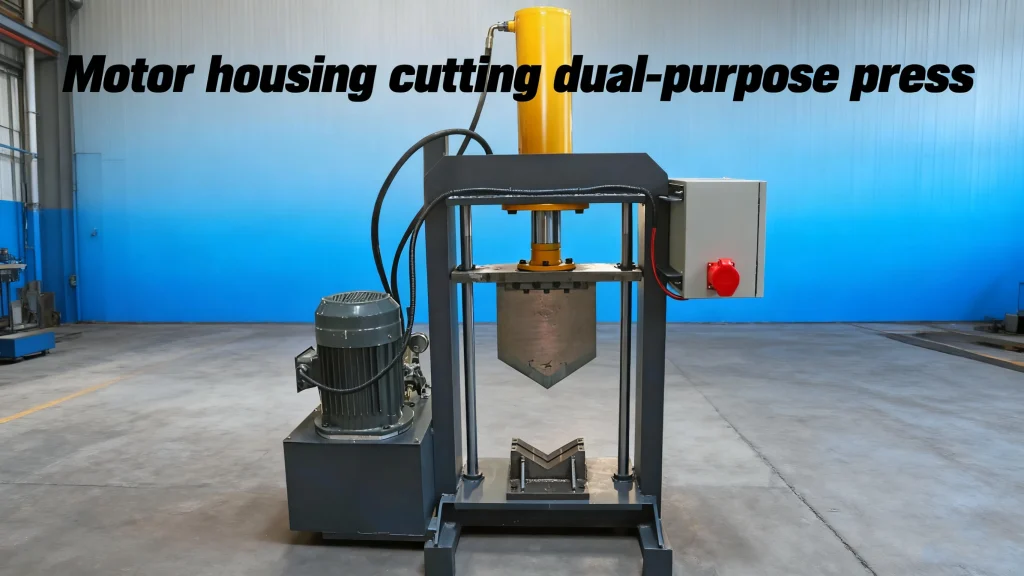

Motor housing cutting dual-purpose press is a versatile multi-purpose press that can be used for any operation that requires pressure, such as the installation and removal of bearings, gears, pulleys, etc. Its application in motors is mainly suitable for the disassembly of three-phase asynchronous motor housings and the cutting of motor stators. Use a small cutter to break open the cast iron housing of the motor, and then use a large cutter to cut the stator core from the middle of the stator. The machine mainly consists of: main frame, cylinder parts, crossbeam parts, V-shaped base parts, guide parts, electrical parts, and hydraulic systems. The whole machine has a reasonable structure, easy operation, safe use, and more reliable performance. The equipment is equipped with two different cutters for dual use. The small cutter is suitable for breaking open the motor housing, and the large cutter is suitable for cutting the stator core. The machine reduces the labor intensity of workers and improves labor productivity. Streamline some

Operation process

1.First, pour #46 hydraulic oil into the machine’s oil tank (tank capacity: 60 liters)

2.Correctly connect the power supply and press the start buttonto activate the equipment.

3.Operate the control handle to move the hydraulic cylinder up/dlown. If it doesn’t work,open the

distribution box and swap the live wires of the power input (change phaase sequence).

4.Breaking motor housing:

4.1 Place the used motor housing (with rotor and end covers removed)on the steel plate of the

base, ensuring stable placement.

4.2 Install the small cutting blade and operate the handle to breaak open the cast iron housing

5.Cutting motor stator:

5.1 Install the large cutting blade and remove the steel plate from the base

5.2 Horizontally place the motor stator at the center position of the V-block, ensuring it’s stable with

outshaking.

5.3 Operate the handle to cut open the stator.

Machine structure