The Motor Shell & Stator Dismantling Machine is primarily suitable for disassembling stators of three-phase asynchronous motors, household appliance stators, and other motors.

A small cutter cuts the motor’s cast iron casing, a large cutter cuts the stator, and a wire-removing mechanism removes the copper wire inside the stator. This equipment can independently complete the entire motor disassembly process from start to finish.

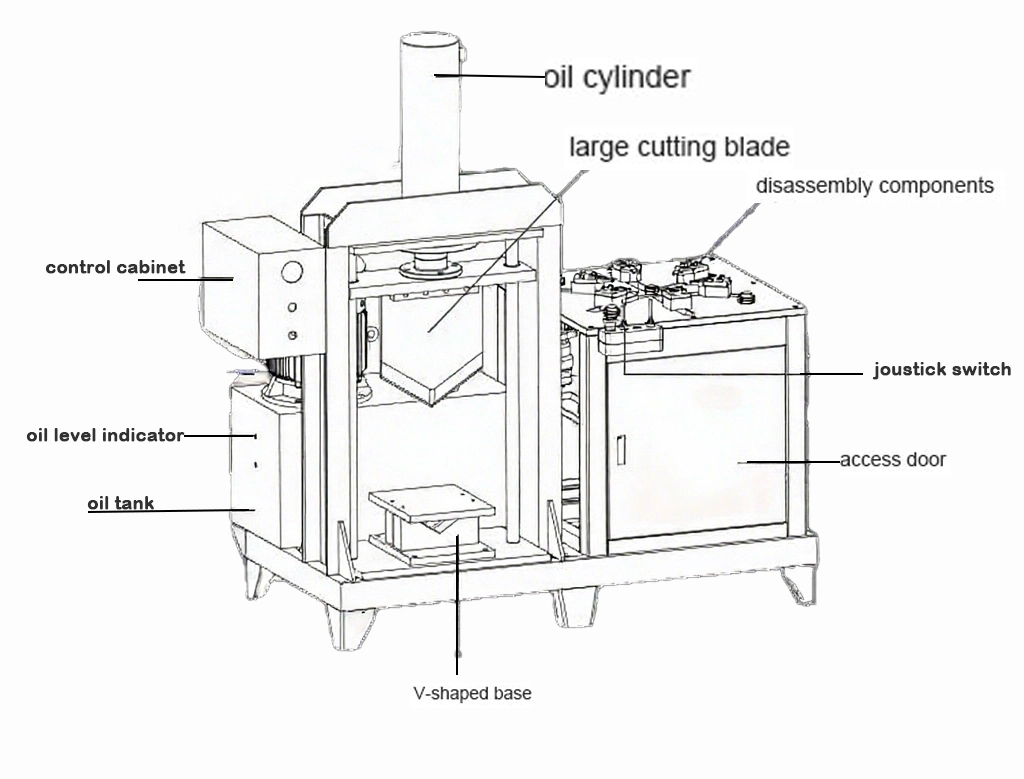

The machine primarily consists of a main frame, wire cutting and wire-removing components, electrical components, and a hydraulic system. Its rational structure ensures easy operation, safety, and reliable performance.

The equipment is equipped with two different cutter mechanisms, one for handling the motor’s cast iron casing and one for handling the stator. This reduces labor intensity and improves productivity.

Operation process

A.Preparation:

1. first of all, add 46# anti-wear hydraulic oil into the machinetank;

2. Connect the power supply: three-phase 380V50Hz (except speccial voltage);

3,press the green start button,the motor runs.

B.Cut shell

1. Remove the rotor,front cover and back cover of the motoor,

2. Place the removed motor shell on the steel plate at the bottom cof the machine to ensure smooth

and no shaking.

3. Use the small cutter, lock the screws, install firmly and ensure vertical. The small cutter is used to

break the motor shell, and the big cutter is used to cut the staator coil

4. Operate the machine control handle,the small cutter downwardmovement, you can break open

themotorshell.

C .Cut stator

1. Place the broken stator coil on the V-block to ensure that the center of the stator is in the middle

of the V-base. Use the big cutter, lock the screws, install firmly and ensure vertical

2. Operate the machine control handle, the big cutter downward movement, you can cut the stator

Machine structure