In today’s fast-paced world, electric motors power everything—from cars and appliances to industrial machines. As global industries shift toward sustainability, motor recycling has become more critical than ever. One of the most effective and eco-friendly solutions is the motor stator and rotor recycling line, a complete system designed to recover valuable materials like copper, aluminum, and steel from used motors.

But how does this system work? What makes it efficient? And why should recyclers invest in a dedicated stator and rotor recycling line? Let’s explore everything you need to know.

What Is a Motor Stator and Rotor Recycling Line?

A motor stator and rotor recycling line is a specialized system that automatically dismantles and separates the key components of waste electric motors.

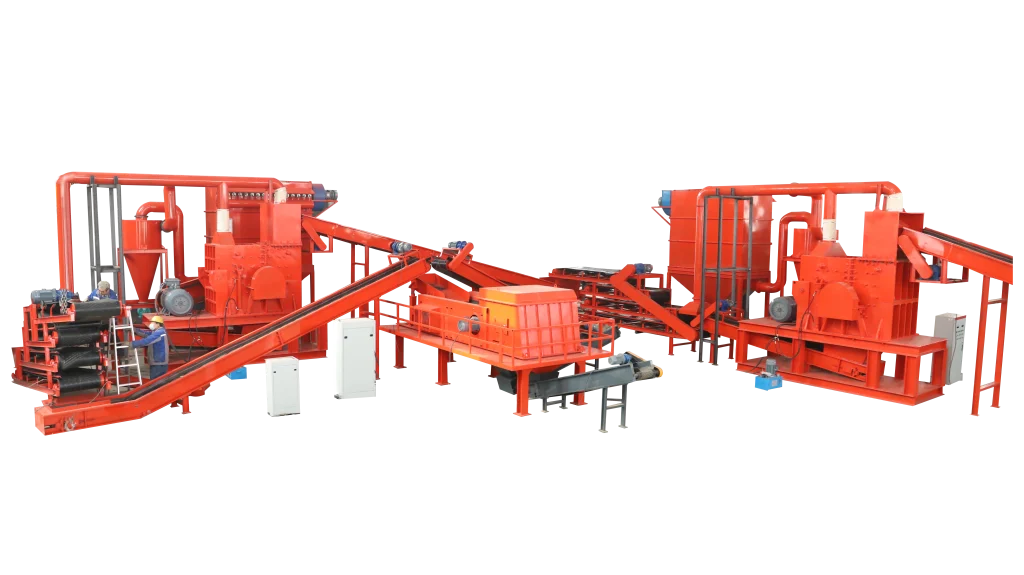

Motor stator and rotor recycling line

Why Motor Recycling Matters

The demand for copper and rare metals continues to grow rapidly—especially with the rise of electric vehicles (EVs). A single electric motor can contain 1–4 kg of copper, and with millions of motors scrapped annually, efficient recycling systems can save tons of resources while minimizing landfill waste.

Traditional manual dismantling methods are slow, unsafe, and often wasteful. By contrast, an automated stator and rotor recycling line improves productivity by up to 400% and recovers over 98% of valuable materials.

Key Advantages of a Stator and Rotor Recycling Line

- High Efficiency – Capable of processing up to 100–500 motors per hour, depending on the model.

- Precision Separation – Ensures nearly zero copper loss and high purity in output materials.

- Safety and Automation – Reduces manual labor and safety risks associated with cutting and handling.

- Energy Saving and Eco-Friendly – Operates with low power consumption and minimal noise.

- Cost-Effective – Rapid payback through recovered copper and reduced labor costs.

Frequently Asked Questions (FAQs)

1. Can this recycling line handle all types of motors?

Yes. It can process a wide range of motors including household appliance motors, industrial motors, automotive motors, and even small EV motors with minor adjustments.

2. How pure is the recovered copper?

Typically, purity levels exceed 98–99%, making the copper suitable for direct resale or smelting.

3. Is the line suitable for large-scale industrial use?

Absolutely. The system is modular—scalable from small workshops to large recycling facilities.

4. What is the maintenance requirement?

Routine cleaning and lubrication are sufficient. Key components are made from wear-resistant steel to ensure long service life.

5. What about environmental compliance?

Modern recycling lines are equipped with dust collection, noise reduction, and filtration systems that comply with global environmental standards.

The motor stator and rotor recycling line is more than just a machine—it’s a complete solution that transforms waste into wealth. With the right setup, recyclers can boost productivity, recover valuable materials, and contribute to a greener planet.

If you’re in the recycling industry, now is the time to upgrade to an automated system that offers efficiency, profitability, and sustainability all in one.