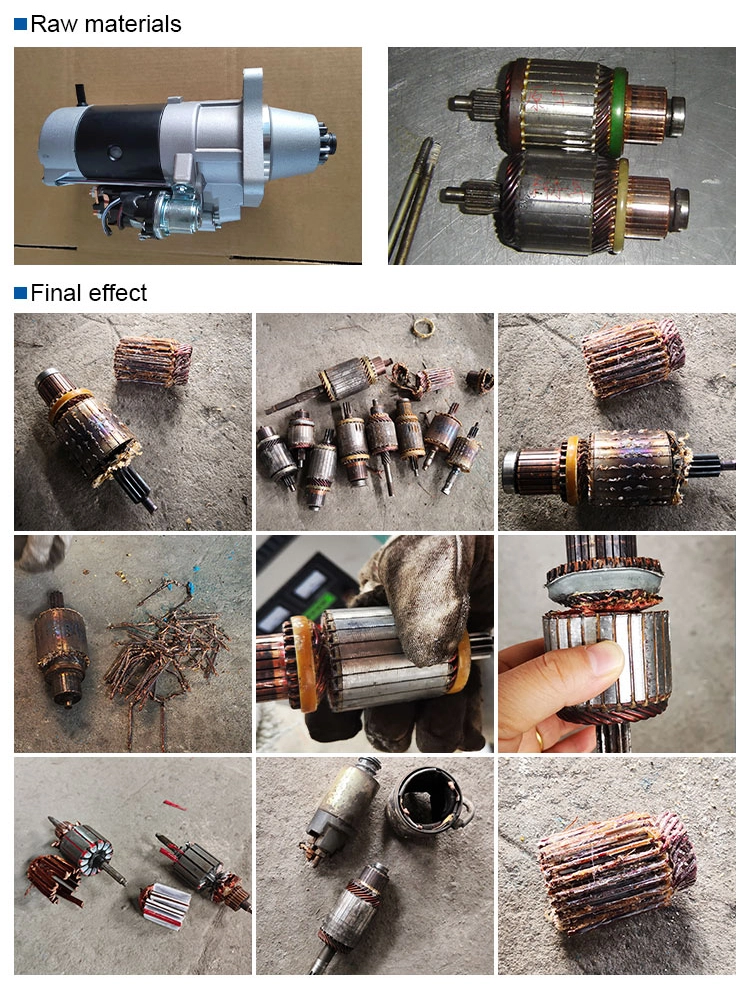

Automobile rotor dismantling machine is mainly used for dismantling automotive starter motor rotors. The cutting device severs one end of the rotor (the bakelite end) while preserving the central shaft intact. The rotor is then heated using our company’s heating equipment to melt the internal insulating adhesive, after which the wire-dismantling assembly removes all the internal copper wires in one operation.

When dismantling automotive starter motor rotors, heating treatment is mandatory. This is because the insulating varnish inside the rotor is too thick, having solidified the copper wires and rotor core into one unit during manufacturing, thus requiring heating for successful dismantling.

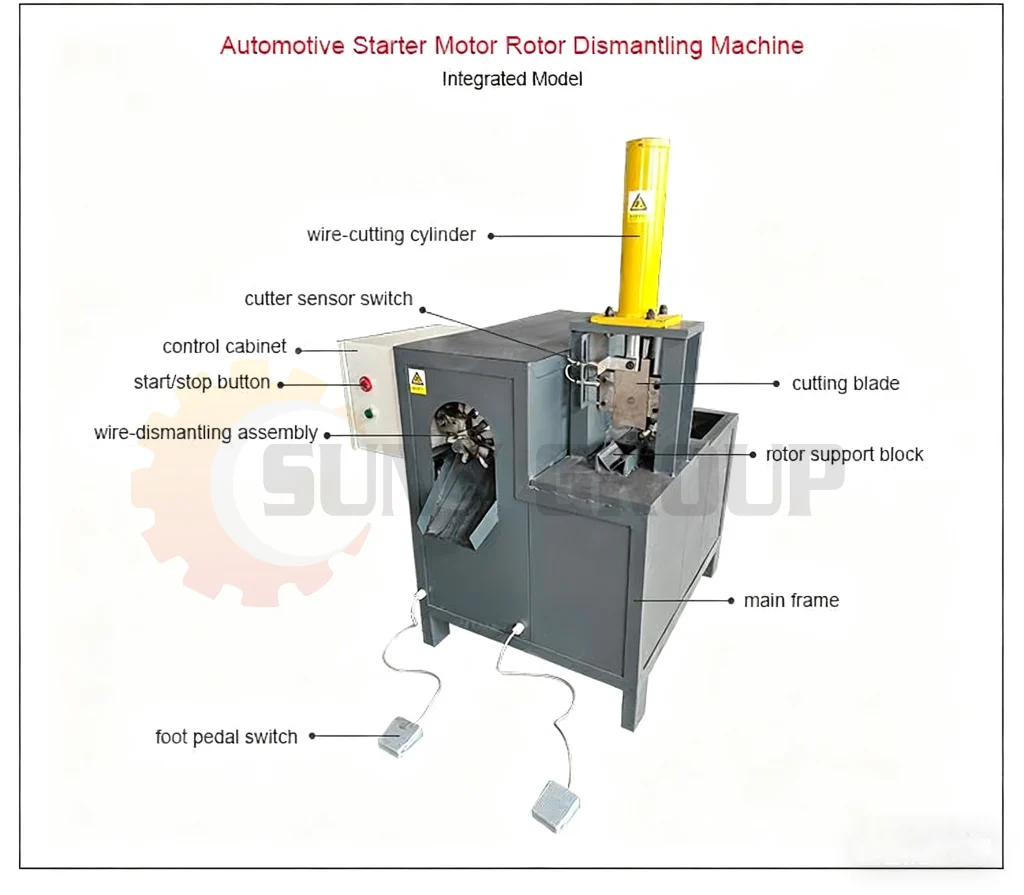

The machine mainly consists of: main frame, hydraulic cylinder assembly, wire-cutting assembly, wire-dismantling assembly, electrical system, and hydraulic system.

The entire machine features rational structure, simple operation, and safe, reliable performance. This equipment can effectively reduce labor intensity and improve production efficiency.

Operation process

A. Preparation

1.Fill the machine oil tank with #46 anti-wear hydraulic oil.

2. Connect to three-phase 380V/50Hz power supply (except for speccial voltages)

3.Press the green start button to activate the motor.

B.WireCutting

1.Step on the wire-cutting foot pedal to lower the cutting tool.

2.After cutting the copper wire, the tool retracts automatically.

3.Rotate the rotor core and repeat the process to completely nemove copper wires from one end

Note: Use momentary pedal control – do NOT keep it pressed continuously

C. Wire Removal

1. Heat the pre-cut rotor to melt internal insulation adhesive

2.Place the rotor in the wire-gripping pusher hole.

3.Press and hold the wire-removal foot switch for 3-5 seconds

3.1Thegripperclaws first secure the copper wires

3.2The central pusher then ejects the core assembly

Machine structure