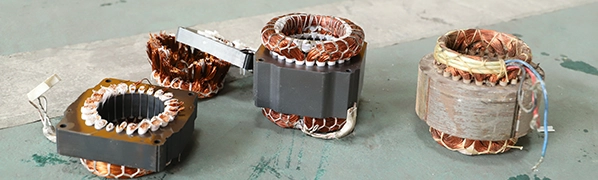

Multifunctional Motor Stator Dismantling Machine is mainly designed for dismantling stators of three-phase asynchronous motors, household appliance motors, and other types of electrical motors.

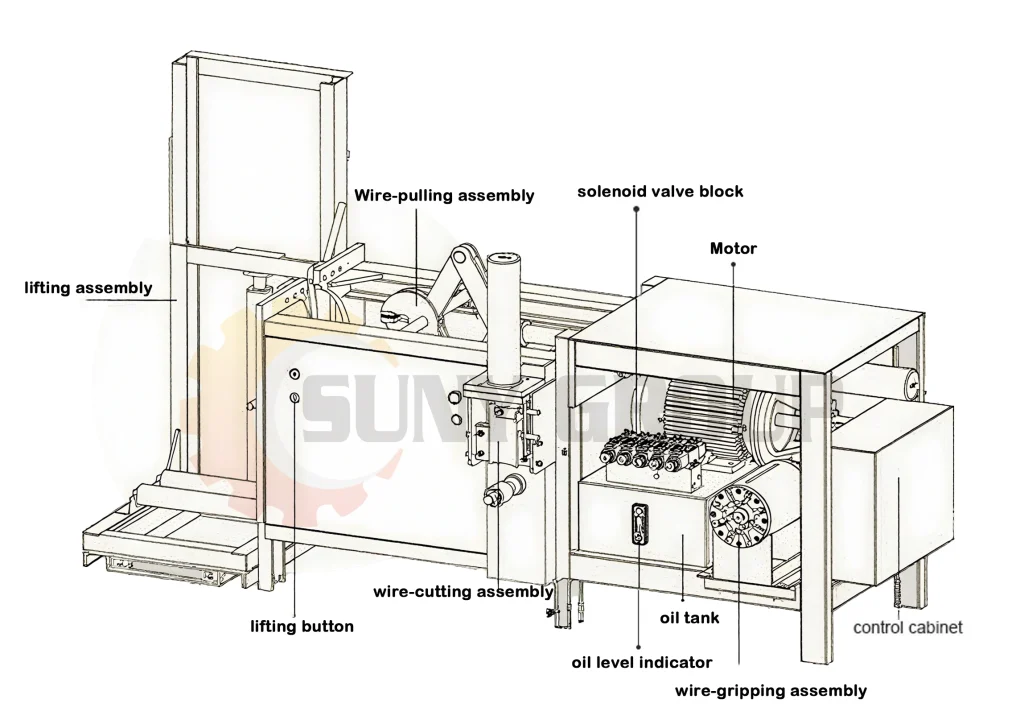

The cutting blade is used to remove copper windings from one end of the stator, followed by a hydraulic system that rapidly extracts the internal copper wires from the stator core.The machine primarily consists of: main frame, lifting assembly, wire-cutting assembly, wire-pulling assembly, wire-gripping assembly, electrical system, and hydraulic system.

The entire machine features rational structure design, simple operation, safe usage, and reliable performance.

The equipment is equipped with two different wire-dismantling assemblies, allowing users to select the appropriate component based on stator dimensions. This machine effectively reduces labor intensity while improving production efficiency.

Operation process

A. Preparation

Fill the machine oil tank with #46 anti-wear hydraulic oil.

Connect power supply: 3-phase 380V 50Hz (4-wire system), unless special voltage is required

Release the emergency stop button and press the green startbutton to activate the motor.

B. Stator Cutting

Place the stator on the wire-cutting assembly.

Step on the cutting foot pedal to lower the blade and cut a section ofcopper windings.

Rotate the stator and repeat the cutting process

After a full rotation, one end of the stator windings will be completelysevered

C. Coil Removal

Small Stator

Place the stator (cut end facing outward, uncut end inward) onthe wire-gripping mandrel.

Step on the coil removal foot pedal to extract the internal copper windings

Large Stator

Place the stator (cut end on the left, uncut end on the right) onthe lifting platform.

Press the lifting button to adjust to the optimal dismantling heigght.

Secure the stator core with the wire removal baffle.

Operate the wire-pulling pliers:

Stainless steel button: Moves pliers forward.

Trigger button: Retracts pliers backward

Clamp the copper windings, then press the trigger to remove the inteernal coils

Mainchine Structure