The Plasma Compressor Cutting Machine is mainly used for shell dismantling of air conditioner compressors and refrigerator compressors. The plasma cutting technology can quickly break open the shell, making it more conve- nient and faster to extract internal coils and other components.

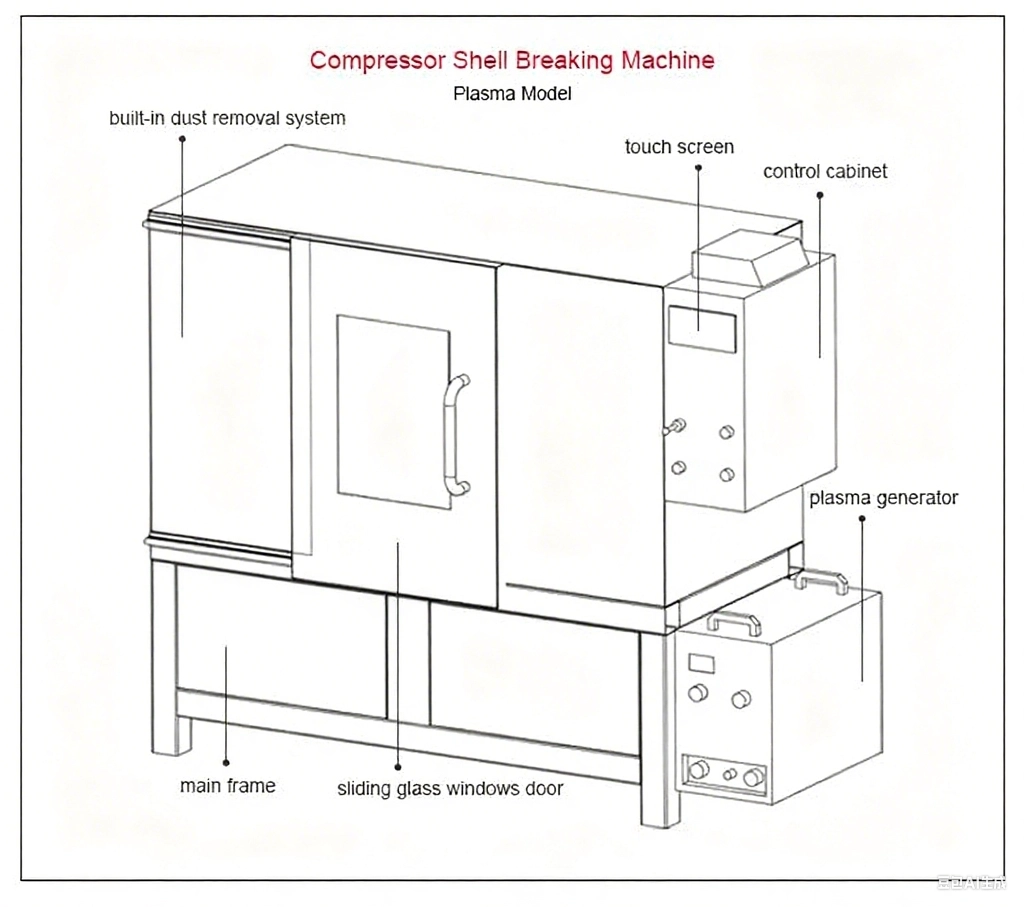

The machine mainly consists of: main frame, lifting assembly, rotating assembly, electrical components, fume extraction device, plasma cutter, human-machine interface and tracking system. The whole machine has reasonable structure, simple operation, safe use and more reliable performance. The equipment is equipped with three different cutting modes. Users can freely select the appropriate mode in the system for cutting, combined with the fume extraction system. During operation, it greatly improves the working environment, reduces labor intensity and increases labor productivity.

Operation process

1.Surface inspection: After unpacking the equipment, carefullycheck the exterior for damage,

including paint scratches. Inspect external components like thecontrol cabinet and plasma generator

for impact marks.

2.Electrical circuit check: Open the control cabinet to verify ifany electrical components have

become loose or detached during transportation.

3.Pneumatic circuit check: Examine all pneumatic components for damage, including the oil-water

separator and pneumatic solenoid valves.

4. Documentation check: Confirm no missing equipment certificates or safety labels on any parts

5.Installation: The equipment must be placed on a level surface and properly leveled. Anchor

screws should be grouted when necessary.

6.Power input: Connect three-phase power supply (3-phase 4-wire system) according to terminal

markings U, V, W, N.

7.Air supply: Connect 010 compressed air tube to the oil-water separrator’s air inlet port

Machine structure