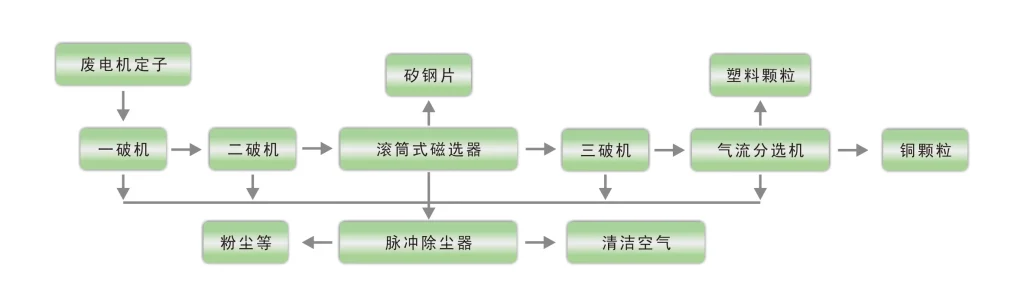

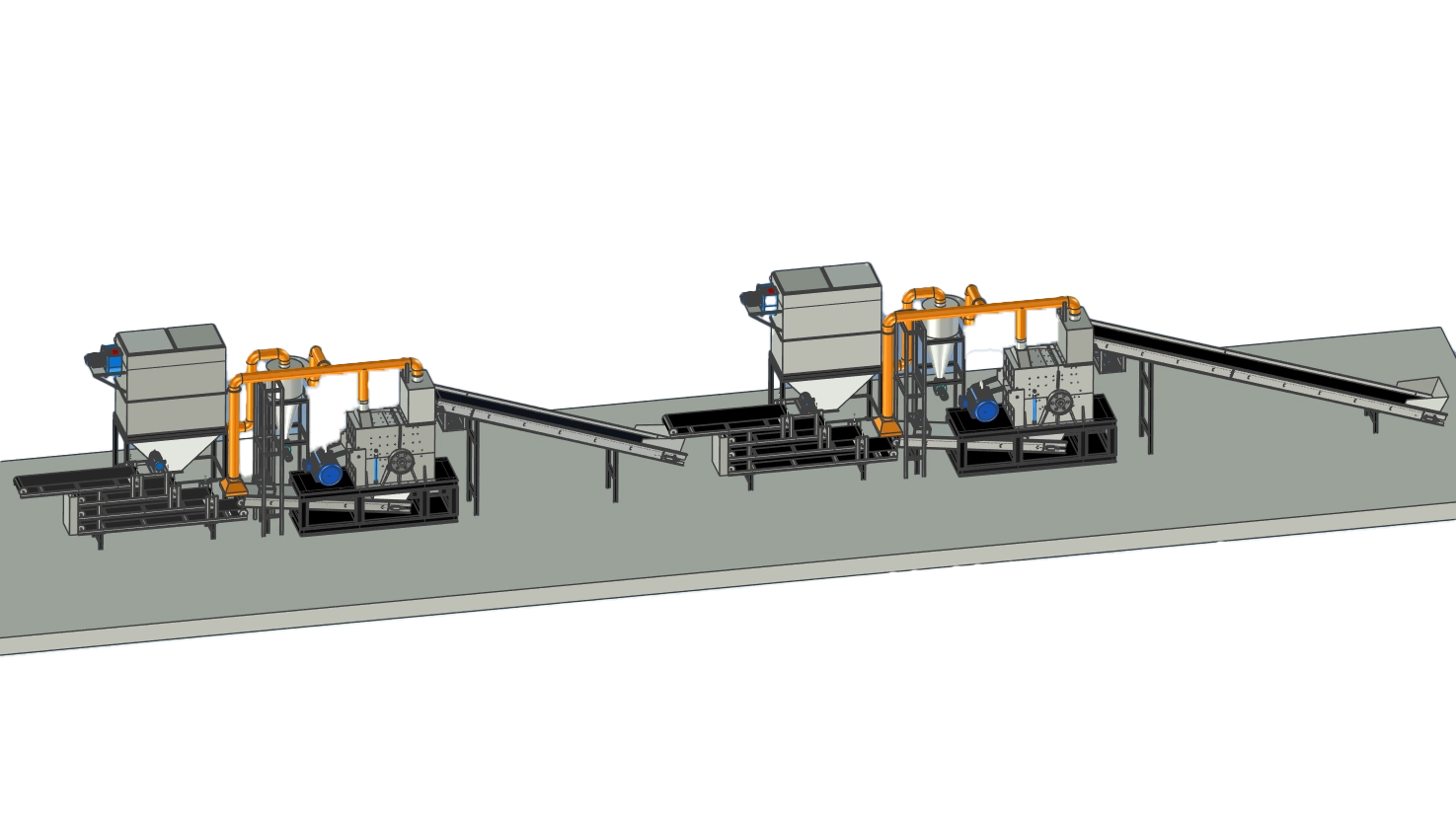

The electric motor stator scrap recycling line transports pre-sorted scrap motor stators, windings, and other materials via conveyors to primary and secondary crushing. A strong magnetic roller separator then separates the silicon steel sheets and copper mixture. The copper mixture is then conveyed by conveyor to a crusher for further crushing and refinement, resulting in a higher-purity product. This product is then conveyed by conveyor to an airflow separator for separation, yielding high-purity copper particles and a small amount of non-metallic materials. This system achieves significant economic benefits. The system utilizes negative pressure suction throughout the crushing and sorting process, along with a pulsed dust removal device, to effectively control dust spillage and environmental impact.

Core Equipment

- Pre-treatment System

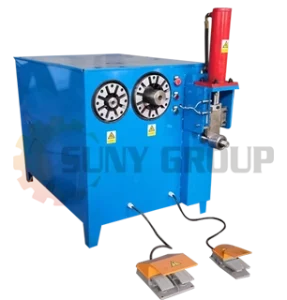

- Dismantling Table: Manual or mechanical removal of shells and fasteners.

- Cutting Machine (Optional): Cuts oversized copper coils into sections for easier feeding.

2.Crushing System

- Dual-Shaft Shear Crusher (Low-Speed, High-Torque): Ideal for copper rotors with iron cores.

- Hammer Crusher (High-Speed Impact): Efficient for pure copper coils.

3.Separation System

- Magnetic Separator: Removes ferrous materials such as silicon steel sheets.

- Eddy Current Separator: Separates aluminum, copper, and non-metallic fractions (plastic, rubber).

- Copper Granulator: Further refines mixed copper, producing clean copper granules while removing non-metallic impurities.

Workflow